NEUTRO ROBERTS SAPONE LIQUIDO NUTRIENTE CON OLIO DI MANDORLA DISPENSER 200 ML CON AZIONE IGIENIZZANTE - PiùMe

NEUTRO ROBERTS Sapone liquido antiscrepolature con olio di argan, 200 ml Acquisti online sempre convenienti | dm Italia

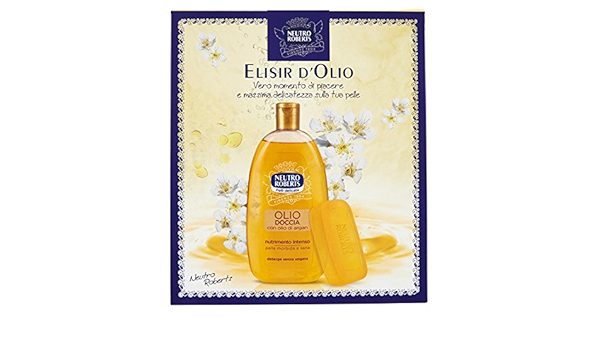

Neutro Roberts Olio Doccia con Olio d'Argan, ottimo per Pelli Delicate, Formula Nutriente e Idratante per una Pelle Morbida e Sana, Deterge Senza Ungere, Flacone da 250 ml : Amazon.it: Bellezza

Neutro Roberts Olio Doccia con Olio di Cocco, Ottimo per Pelli Delicate, Formula Addolcente e Protettiva per una Pelle Morbida e Sana, Deterge e Idrata, non Unge, Flacone da 250 ml :

Neutro Roberts Olio Doccia con Olio di Cocco, Ottimo per Pelli Delicate, Formula Addolcente e Protettiva per una Pelle Morbida e Sana, Deterge e Idrata, non Unge, Flacone da 250 ml : Amazon.it: Bellezza